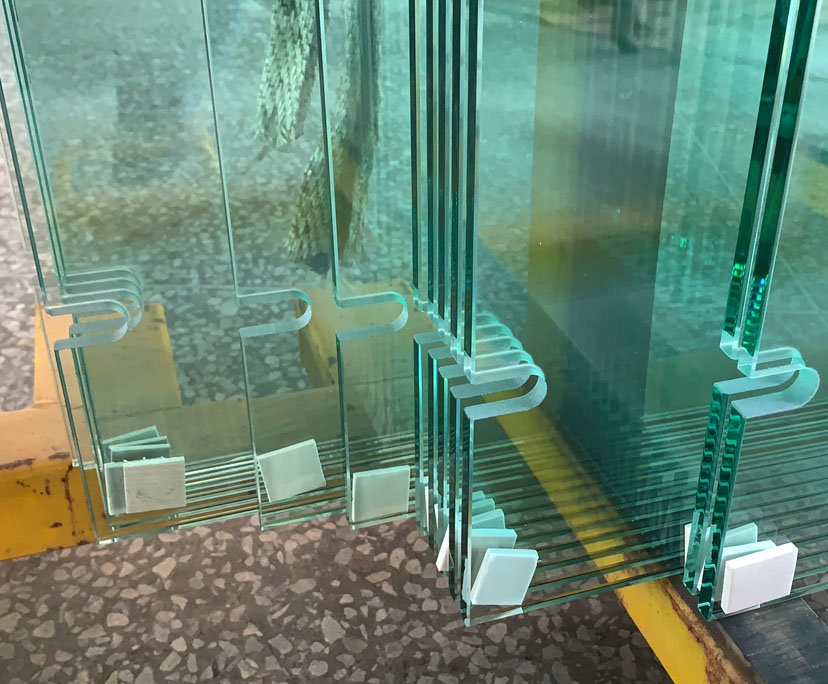

8mm clear tempered toughened reinforced building glass

Product Introduction:

BTG BETTER GLASS 8mm tempered glass qualified with BS6206/EN12150/CSI and SGCC quality standard.

8mm tempered glass/Reinforced glass is a safety glass. 8mm tempered glass is actually a type of prestressed glass. In order to increase the strength of the glass, chemical or physical methods are usually used to form compressive stress on the surface of the glass. When the glass is subjected to external force, the surface stress is first offset, thereby improving the bearing capacity and enhancing the resistance of the glass itself. Wind pressure, cold and heat, impact and so on. Note that it is distinguished from FRP.

Product details

Characteristic of 8mm clear tempered glass

1.safety

When the glass is damaged by an external force, the debris will become a honeycomb-like obtuse-angled small particle, which is not easy to cause serious damage to the human body.

2.high strength

The impact strength of an 8mm tempered glass of the same thickness is 3 to 5 times that of ordinary glass, and the bending strength is 3 to 5 times that of ordinary glass.

3.Thermal stability

8mm tempered glass has good thermal stability, and can withstand a temperature difference of three times that of ordinary glass, and can withstand a temperature difference of 300 °C.

4.advantage

1. The first is that the strength is several times higher than that of ordinary glass and it is resistant to bending.

2. The second is safe use, and its load-bearing capacity is improved to improve the fragile nature. Even if the 8mm tempered glass is broken, it is a small piece with no sharp angle, and the damage to the human body is greatly reduced.

3. The quenching and rapid heat properties of 8mm tempered glass are 3 to 5 times higher than that of ordinary glass and generally can withstand temperature changes of more than 250 degrees, which has obvious effects on preventing thermal cracking. It is one of the safety glasses. To ensure the safety of qualified materials for high-rise buildings.

Disadvantages of 8mm tempered glass:

1. The 8mm tempered glass can no longer be cut and processed, and the glass can only be processed to the required shape before tempering, and then tempered.

2. Although the strength of 8mm tempered glass is stronger than that of ordinary glass, 8mm tempered glass has the possibility of self-explosion (self-rupture), while ordinary glass does not have the possibility of self-explosion.

3. The surface of the 8mm tempered glass will have unevenness (wind spots) and a slight thickness will become thin. The reason for the thinning is that after the glass is melted by hot melt, it is rapidly cooled by a strong wind force so that the internal crystal gap of the glass becomes small and the pressure becomes large, so the glass is thinner after tempering than before tempering. Under normal circumstances, the glass of 4~6mm is thinned by 0.2~0.8mm after tempering, and the glass of 8~20mm is thinned by 0.9~1.8mm after tempering. The degree of specificity depends on the equipment, which is why 8mm tempered glass cannot be mirrored.

4. The flat glass used for construction after passing through the tempering furnace (physical tempering) is generally deformed, and the degree of deformation is determined by the process of equipment and technicians. To a certain extent, it affects the decorative effect (except for special needs).

Production

8mm tempered glass is obtained by first cutting the ordinary annealed glass into the required size and then heating it to about 700 degrees near the softening point, and then performing rapid and uniform cooling (usually 5-6MM glass is heated at 700 °C for 240 seconds). Cool down for about 150 seconds. 8-10MM glass is heated at 700 °C for about 500 seconds, and the temperature is lowered by about 300 seconds. In short, depending on the thickness of the glass, the time for heating and cooling is different. After the tempering treatment, the surface of the glass forms uniform compressive stress, while the inside forms tensile stress, which improves the bending and impact strength of the glass, and its strength is about four times that of the ordinary annealed glass. The 8mm tempered glass that has been tempered can no longer be processed or damaged by any cutting, grinding, etc., otherwise, it will “break the bones” due to the failure of the uniform compressive stress.

if you want to know more information about the BTG glass company, please click the link as below:

https://www.better-glass.com/news-events/